Heat Guns

Hapco, Inc. has been providing the best heat guns on the market for every industry. From commercial roofing to banner welding, our heat guns are the reliable plastic welding tools you are looking for. Whatever welding project you’re working on, we’ll help you choose the best industrial heat gun to execute high-quality welds.

Our Industrial Heat Gun Collection

Our range of industrial heat guns heat air and turns it into a narrow, high-temperature stream that’s used to weld plastics. Also called heat air gun or hand welder, these heat, gun-like tools can also be used for other purposes, such as roofing, drying paint and thawing frozen pipes.

Our range of heat guns is great for industrial purposes. Built with high quality materials, they are long lasting, easily repairable, and come with additional warranties.

All Our Heat Guns

-

BAK ErOn Heat Gun

$0.00 Select options- Hand welder

- Air flow 600 l/min

- Best for corners & narrow spaces

-

BAK LiiOn – Battery Powered Heat Gun

$0.00- Battery powered hand welder

- Air flow 150 l/min

- Best for quick welds

SKU: 6600434

Add to Quote -

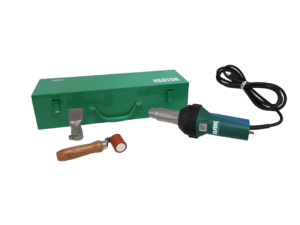

BAK RiOn Basic Kit

$0.00- BAK RiOn 120V 1600W

- 40mm nozzle & 40mm roller

- Toolbox

SKU: 6600160BK

Add to Quote -

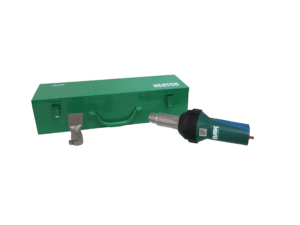

BAK RiOn Deluxe Kit

$0.00- BAK RiOn 120V 1600W

- 7 heat gun parts and accessories

- Toolbox

SKU: 6600160DK

Add to Quote -

BAK RiOn Heat gun

$0.00 Select options- Hand welder

- Air flow 250 l/min

- Best for corners & narrow spaces

-

BAK RiOn Portable Repair Kit

$0.00- BAK RiOn 120V 1600W

- Honda EB2200 generator

- Toolbox & Accessories

SKU: PRK2000EB

Add to Quote -

BAK RiOn Premium Kit

$0.00- BAK RiOn 120V 1600W

- 7 heat gun accessories

- Toolbox

SKU: 6600160P

Add to Quote -

BAK RiOn with 20mm Nozzle

$0.00- BAK RiOn 120V 1600W

- 20mm Nozzle

- Best for detailed hand welding

SKU: 5100726N20

Add to Quote -

BAK RiOn with 20mm Nozzle and Metal Toolbox

$0.00- BAK RiOn 120V 1600W

- 20mm Nozzle

- Toolbox

SKU: 5100726N20B

Add to Quote -

BAK RiOn with 40mm Nozzle and Metal Toolbox

$0.00- BAK RiOn 120V 1600W

- 40mm Nozzle

- Toolbox

SKU: 5100726NB

Add to Quote -

BAK WeldOn

$0.00 Select options- Digital Adjustable Hand welder

- Air flow 40 l/min, 1000W

- For industrial fabrication

Why Choose BAK Heat Guns

The commercial roofing, oil, gas, and geotextile industries use heat guns primarily for plastic welding such as TPO or PVC. By producing the leading industrial heat guns on the market today, BAK hot air guns and heat welders are popular in many industries. Here are six reasons why you should invest in a BAK heat gun such as the BAK RiOn roofing heat gun for your plastic welding projects:

1 – Durable

BAK heat guns contain metal screws at every joint, making them more durable and less likely to crack than heat guns containing plastic screws. The metal screws of a BAK heat gun also make it possible to handle heavier-duty plastic welding projects.

2 – High-Quality

Unlike its competitors, a BAK heat gun contains one circuit board. This lowers the chances of circuit board failure. Another perk of BAK heat guns is that the circuit board’s placement is away from the hot air gun’s heat source, which prevents the circuit from breaking down mid-weld due to overheating.

3 – Ergonomic

The more efficient shape of the BAK RiOn heat gun’s handle makes it easier to use than competing heat guns, and its soft grip is more comfortable to hold when performing plastic welds.

4 – Efficient

The motor carbon brushes in BAK heat guns are longer than those found in competing industrial hot air guns. The extra surface area on the brush enhances the heat gun’s usability and extends the life of the motor by up to 20%.

5 – Low Maintenance

Since multiple BAK industrial heat gun components are interchangeable, you can easily replace them when they malfunction or break down. Should that ever happen, Hapco Inc also offers equipment repair services for heating guns and hand welders.

6 – Reliable

BAK heat guns are the most reliable in the welding tool industry. Especially when compared to Leister heat guns, BAK heat guns are superior in terms of durability, safety, efficiency and build quality.

The Hapco Quality

Quality Comes First

We buy the best heat guns directly from Switzerland, package them for customers, and deliver it to you for easy use or reselling. It’s a turnkey solution that makes it simple and efficient for our distributor partners.

With over 30 years of experience in the industry, Hapco Inc. is the best partner for all your needs in heat guns, welding tools, generators, pumps and extruders.