When it comes to plastic welding, knowledge is key to having your work last for a very long time.

Wondering what the differences are between TPO and PVC for welding projects? Want to know which material is better for your roofing needs?

Keep reading to find out everything you need to know about TPO and PVC roofing.

What Is TPO Roofing?

TPO stands for thermoplastic polyolefin. This single-ply membrane can be made with either ethylene or polyethylene thermoplastic that’s connected to ethylene-propylene rubber. TPO is used to make welds in residential and commercial roofing projects on roofs that are flat or have a low slope.

TPO is a favorable welding material for roofing jobs because it’s durable, energy-efficient, and designed with longevity in mind. TPO has some flexibility but is less flexible than PVC. As a result, TPO can be difficult to welding in tight, curved spaces. Its thermoplastic and rubber components make TPO highly resistant to harsh chemicals, strong winds, oil spills, and punctures. It also holds up well in extreme temperatures—without buckling—and withstands weathering. TPO is a cost-effective roofing solution that’s easy to weld.

What Is PVC Roofing?

PVC stands for polyvinyl chloride. Like TPO, PVC is a single-ply membrane used to make welds for residential and commercial roofing projects. Unlike TPO, PVC is made with polymerized vinyl chloride monomers and plasticizers that enhance flexibility. PVC is intended for welding use on flat and low-slope roofs only.

PVC is a popular welding material for roofing jobs because it’s thick yet still flexible enough to withstand severe heat and weathering without cracking under pressure. PVC is also recyclable and has a high resistance to harsh chemicals, strong winds, oil spills, punctures, fire, and UV rays. If one thing is sure about this cost-effective, plastic welding material, it’s that PVC is built to last.

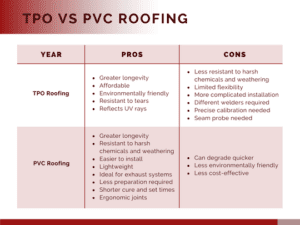

Pros & Cons of TPO vs PVC Roofing

When choosing between TPO vs. PVC to perform welds for roofing jobs, it all comes down to membrane and installation quality. With that said, each roofing material has distinct advantages and disadvantages that should be considered before committing to one.

Two qualities that TPO and PVC share are their energy efficiency and longevity. Since both welding membranes are highly UV resistant—meaning they keep heat out of buildings—they’re equally energy-efficient. Both welding membranes are also extremely durable, which means they’re long-lasting.

Take a look below at the top pros and cons of PVC vs TPO welding materials for roofing jobs:

TPO Pros

- Greater longevity

- More affordable to purchase and have installed

- More environmentally friendly

- More resistant to tears and breaks

- Reflects UV rays

TPO Cons

- Less resistant to harsh chemicals, punctures, and weathering

- Limited flexibility

- More complicated installation process

- Different welders are required for long seams and short seams

- Contractors must calibrate the welding machine correctly. Otherwise, seams may come loose during the first freeze/thaw cycle and lead to water infiltration.

- After both the walk-behind and hand-held welding, a seam probe is needed to check the welds. If the welding doesn’t take, it requires patching.

PVC Pros

- Greater longevity

- More resistant to harsh chemicals, punctures, weathering, and fire

- Easier to install

- Watertight

- Lightweight

- Backed by decades of use in the roofing industry

- More affordable installation process

- Ideal for roofs with an exhaust system or a grease trap, like restaurants

- Involves fewer surface preparation requirements before welding

- Shorter cure and set times, depending on the welding method

- More ergonomic joints and aesthetically pleasing bonds

PVC Cons

- Can degrade more quickly

- Less environmentally friendly

- Less cost-effective

The Importance of Having Reliable Heating Tools on Hand for Every Welding Job

When you have reliable heating tools and accessories on hand, you can rest easy knowing the equipment you have will get the job done right the first time, every time. You’ll also have everything needed to install new roofs and make necessary repairs and replacements when issues arise. Having quality commercial roofing tools also reduces the likelihood that you’ll need to make roof repairs and replacements in the first place.

Whether you opt for an automatic welding machine, a battery-powered heat gun or a traditional hot air blower, you should keep in mind both functionality and ease of use.

Your #1 Destination for Commercial Roofing Tools

Hapco, Inc. is the trusted roofing tools supplier for customers across the United States, Canada, and Mexico. With over 30 years of experience in the commercial roofing industry, we have all the right heating tools for your next roofing project.

Comments are closed.

Recent Comments